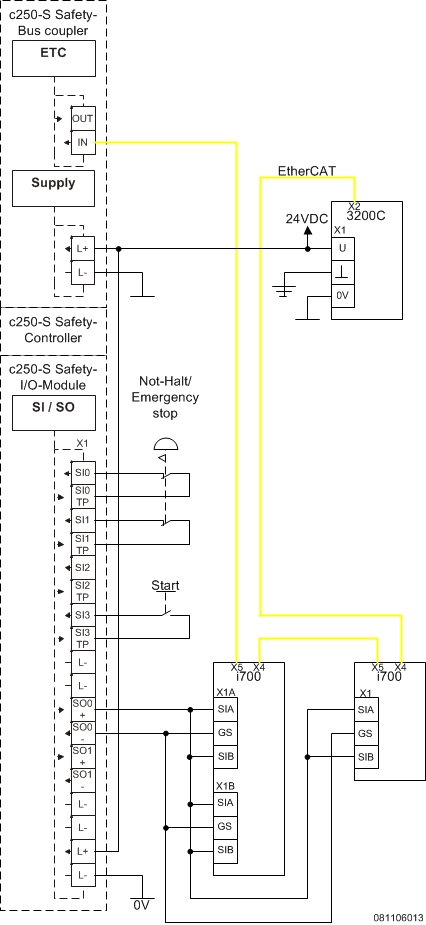

Function:When the emergency-stop button is actuated, the motors are stopped according to stop category 1 of EN 60204-1. (Safe stop 1 according to DIN EN 61800-5-2:2008-04 chapter 4.2.2.3 function c)

All axes are installed in the same hazardous area.

The delay time of the “Safety” program must be longer than the resulting xStop time. Consider the delay time tolerances in the safety PLC.

The values to be set depend on the application.

Faults have been excluded for protected cables (according to DIN EN ISO 13849-2:2013-02 and IEC 61800-5-2:2008-04). This applies to cables which are protected by a cable duct and installed inside the control cabinet.

Safety information / disclaimer:

The safety application and parameterisation notes are examples of possible subfunctions in machines.The

T10D value according to DIN EN ISO 13849-1, Annex C.4.2 is only

indicated if a B10D value is available and the operating time is less

than 20 years. Commissioning

is prohibited until the machine has been checked in accordance with the

regulations set out in the relevant EU directives / national laws. The safety instructions contained in the technical documentation must be observed. Using

the examples does not exempt the user from careful project planning.

For possible damages and consequential damages Lenze assumes no

liability to the extent permitted by law. Copyright 2019 Lenze Automation GmbH