Which products are affected?

9300EP position controller V7.0

9300ES servo controller V7.0

Eliminated function restriction

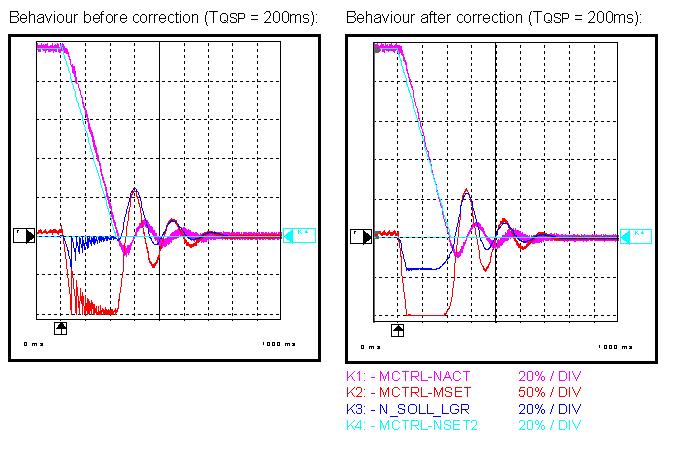

If the torque setpoint (MCTRL-MSET2 signal) reaches the torque limit Mmax while the QSP ramp is executed, short-term torque dips might have occurred up to now. As a result, the time required for executing the QSP ramp might have been prolonged. This effect has been produced by setting the integral action component of the speed controller to zero when the torque limit has been achieved. Now, the integral action component is no longer completely set to zero but only limited in an adequate way in order to stop continuously by applying the max. torque and to suppress a reverse rotation or drift during standstill.

Which products are affected?

9300EP position controller <= V6.2

9300ES servo controller <= V6.2

What happens?

If the torque setpoint (MCTRL-MSET2 signal) reaches the torque limit Mmax while the QSP ramp is executed, short-term torque dips may occur. As a result, the time required for executing the QSP ramp may be prolonged.

When does the problem occur?

If the QSP deceleration time under C0105 is set so short that the drive cannot generate the torque required for the resulting QSP ramp without reaching the torque limitation (Mmax).

Possible diagnostics?

Record the torque sequence (MCTRL-MSET2) while the QSP ramp is executed and observe the MCTRL-MMAX output signal.

Short-term measures/recommendations?

Prolong the QSP deceleration time under C0105 to such an extent that the drive can adhere to the ramp without reaching the torque limit.

Evaluation:

The drive can be stopped reliably despite this problem.