Energy efficient drive solutions for industry and the environment

Why is energy efficiency needed in industry?

Sustainability and climate protection already play an increasingly important role in the private sphere. In industry, too, the importance is increasing: In order to reconcile climate targets with a growing and prosperity-oriented society, increasing energy efficiency in industry is a key lever for reducing energy requirements and limiting global warming.

Drive systems are responsible for about 70% of the electricity demand in industry. This makes them the biggest lever for increasing energy efficiency and reducing energy demand. The mechanical engineering industry is facing increasing legal requirements, such as the Ecodesign Directive European Green Deal , and the growing desire of users. Lenze provides concrete and holistic support in optimizing the energy requirements of machines with energy efficient drive solutions in 4 steps.

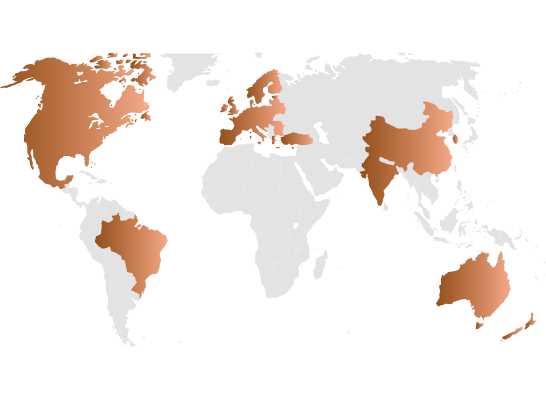

International requirements for energy efficiency

The IEC60034-30-1 standard describes energy efficiency classes for three-phase motors using IE codes. However, the standard does not specify any efficiency classes to be complied with. This is done in the regional legislation. As a result, there are requirements for the minimum efficiency of electric motors in almost all markets. We have prepared these country-specific requirements clearly for you and they are available for download here.

Intelligent drive sizing

Lenze System Designer

Intelligent drive sizing is a prerequisite for an exactly dimensioned and therefore small-as-possible drive solution with just the right components. Thanks to the System Designer potential energy savings become transparent right from the planning stage. A clear comparison of different solutions is also made easy.

After all, the System Designer provides a simple view of complex sizing knowledge, with well-founded expertise of drive applications such as drive physics, variants or energy efficiency. Drives are sized based on calculations with individual process data and speed profiles, taking the complete structure of the drive into consideration for the requirements of the machine.

Energy efficient components

Basis for efficient solutions

Lenze m550 three-phase AC motors already meet all current and known planned energy efficiency regulations, such as efficiency classes IE2, IE3 and now IE5 and IE6. In combination with the efficient g500 gearboxes and i550 drives, this represents a complete and energy-efficient drive to offer very good savings potential:

Utilize regenerative energy

Conserve resources

Regenerating braking energy with the motec decentralized frequency drive has also proven its worth. With the motec's integrated energy recovery system, energy is not wasted but fed back as electricity to other power-consuming components or back into the mains. Both have a positive effect in the short term and an optimized CO2 footprint of the machine in the long term.

The Lenze i550 cabinet drives can also feed energy back into the mains in the DC network. For existing plants, the Lenze r750 regenerative module can be retrofitted by direct connection to the DC link - an investment that pays for itself within a short time.

Optimize with Smart Data

Analyse real-time data

Future generations of machines will benefit from evaluations of real-time data. Not only Condition Monitoring data but also data on energy consumption can be made available by the variable frequency drives, for example via the motec's IO-Link.

This data can be made available to cloud-based services for further processing via the Drives DataHub. Use the process of continuous improvement for further energy savings with Smart Data.