Siemens S7

Supported hardware and firmware

Cloud Notify via Siemens S7 is supported on the x500 in firmware 3.7 and up. Please upgrade your firmware if you are running an older version.

Activate Cloud Notify

Please first activate Cloud Notify (or start the 30 day free trial) if you haven't already.

The second step in Cloud Notify is setting up a data source. This is done by selecting a communication protocol and defining the variables. This article shows you how to do this for a Siemens S7-300/400/1200/1500 PLC.

- PLC settings

- Select a communication protocol

- Add variables

- Test variables

- Manage variables

PLC settings

Using a Siemens LOGO! PLC?This protocol will only work with a Siemens S7-300/400/1200/1500 PLC. For a Siemens LOGO!, you can enable Modbus on the PLC and create a Modbus TCP/IP data source instead.×Dismiss alert

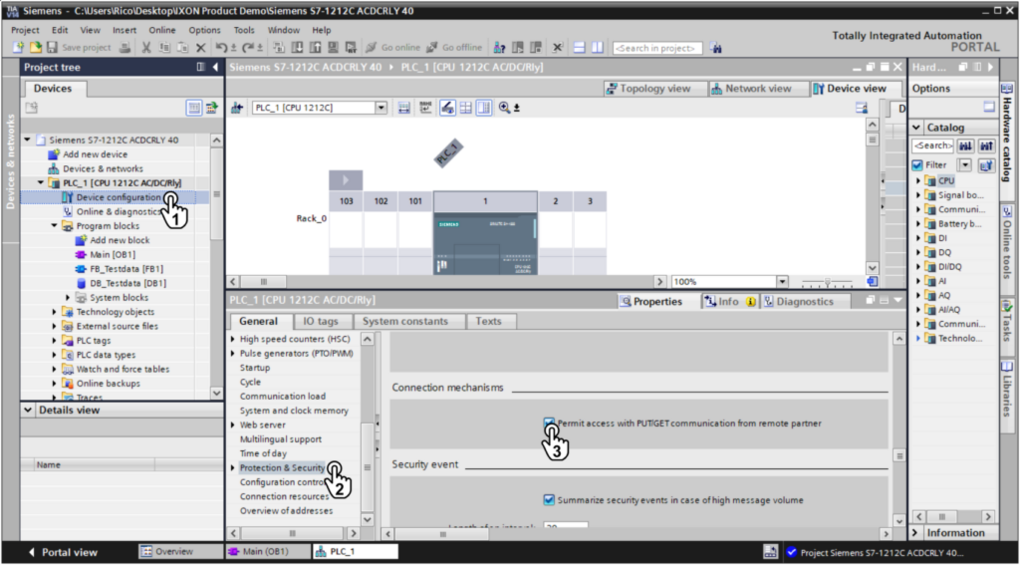

The S7-1200 and S7-1500 PLCs have a built-in firewall. By default, the maximum protection level is activated. The x500 will need access to the PLC.

- In TIA Portal, go to [Device configuration], select [Protection & security] in the properties tab and check the setting “Permit access with PUT/GET communication from remote partner”.

- Finally, download the new hardware configuration to the PLC for the changes to take effect.

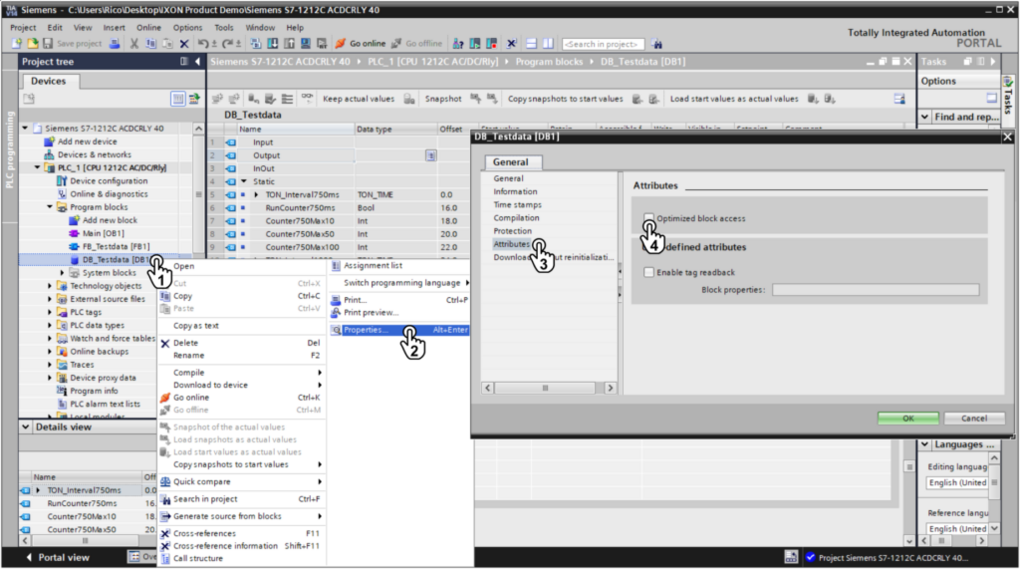

The addresses of data block variables are, by default, optimized by TIA Portal and not visible. If you wish to log data from data blocks, these will need to have “optimized block access” turned off.

- In TIA Portal, right-click a data block, or the linked function block, go to [Properties], select [Attributes], and uncheck “Optimized block access”.

- Finally, compile the TIA Portal project and download the new software to the PLC for the changes to take effect.

Select a communication protocol

You first have to select a communication protocol. This is the protocol that the x500 will use to communicate with the PLC.

- Go to the Fleet Manager app, which is accessible from the Apps menu in the top right corner if you are currently in a different X4 Remote app.

- Open the Main menu, go to Devices, and select the concerning device.

- Click on the Add a service icon in the left menu, select [Data source], and then select [Siemens S7-300/400/1200/1500].

- Enter the requested information (details below) and click on [Add].

| Field | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Enter a name for the data source. | ||||||||||

| Identifier | The identifier ensures that every data source remains unique, even if they share the same name. | ||||||||||

| IP address | Enter the IP address of your PLC. | ||||||||||

| Port | The port number will be entered automatically (Port 102 for Siemens S7). | ||||||||||

| Rack and Slot | Rack and slot number of your PLC (can be seen in TIA Portal > Device configuration). Below is an overview of the default rack and slot numbers.

| ||||||||||

| Polling sleep time | To log data as accurately as possible, the x500 continuously asks the variables’ values from the PLC (this does not count towards your license’s dps/hr). While the x500 does wait for the PLC to reply before asking again, in very rare cases this may noticeably impact the PLC’s performance. In such a rare situation you may want to change this setting to 100ms or higher. In general “None” is recommended for Cloud Logging to be as accurately as possible. |

Add variables

Once you’ve added a data source and selected a communication protocol, you can start adding variables. You can do this by following the steps below:

- Expand the Data source service and go to [Variables].

- You can now choose to:

- Manually add new variables

- Import variables from a file (or device)

Tip!

It is advisable to add variables in small batches and test them to verify their configuration.

Manually add new variables

- Click on [Add variable] in the bottom right corner.

- Enter the requested information (details below) and click on [Add].

| Field | Description |

|---|---|

| Name | Enter a name for the variable. |

| Identifier | The identifier ensures that every variable remains unique, even if they share the same name. |

| Type | Select the variable’s data type (bool, int, float, etc). |

| Length | (for String data types only) The String length. |

| Region | DB (data block), I (input), M (merker) or Q (output) |

| Data block | (available when region “DB” is selected) Enter the data block number. |

| Address | This is called “offset” in TIA Portal. E.g. for “offset” 24.0 you enter 24 as the address value. |

| Bit | (for Boolean data types only) This is called “offset” in TIA Portal. E.g. for “offset” 24.0 you enter 0 as the bit value. |

| Factor | Multiplies the value (leave empty if the data type is boolean). |

| Unit | Displayed text behind the value. |

Temporary disconnect

After this next step, the config push, the device may temporarily disconnect and LAN communication may be temporarily interrupted while it's applying the new settings. This may take a minute.

You have now made the changes in X4 Remote, but these are not yet active in your device. You will need to push your changes to your device for them to take effect.

- Click [Push config to device] in the top right corner.

Next step

Now that you've added the variables, you can test if they're configured properly.

Import variables from a file (or device)

You can easily and effortlessly copy variables from one device to another by exporting the concerning variables (view the “Manage variables” part of this article) and then importing them in your new device. Alternatively, you can manually prepare your variables in the required CSV format to load them all at once into your configurator. The CSV file structure is explained in our Import variables article.

- Click on [Import from CSV-file] in the top right corner of the screen.

- Select a CSV file to import and click on [Open].

Temporary disconnect

After this next step, the config push, the device may temporarily disconnect and LAN communication may be temporarily interrupted while it's applying the new settings. This may take a minute.

You have now made the changes in X4 Remote, but these are not yet active in your device. You will need to push your changes to your device for them to take effect.

- Click [Push config to device] in the top right corner.

Next step

Now that you've added the variables, you can test if they're configured properly.×Dismiss alert

Test variables

The test utility is used to check if all the added variables are set correctly. It shows the communication status with the PLC and displays each variable’s current value if everything is configured correctly. If not, the values will stay empty. The test utility will attempt to update values every 0.5 seconds, regardless of how often it’s actually being logged (this does not count towards your license’s dps/hr). Please follow the steps below to test your variables.

- Expand the Data source service, go to [Variables], and click on [Run test] at the top.

A connection will now be set up to stream the data directly to your computer, using:

| Port | Transport protocol | Application protocol |

|---|---|---|

| 443 | TCP | WebSocket |

You will see live values of all variables, if the configuration is set up correctly.

Unexpected result?

If the test utility shows unexpected values, please check if the addresses and data types of all variables are entered correctly. If you get no data at all, please also check that the above listed port and protocols are not being blocked by your computer's or company's firewall.

Next step

Now that you've tested the variables, you can view our "Configure data tags" guide to start logging.

Manage variables

You can view all defined variables on the variables page:

- Expand the Data source service and go to [Variables].

You can [Edit] individual variables, [Remove] individual or a selection of variables, and export all or a selection of variables.

Variables can be selected by clicking the checkbox on the left, or you can select them all by clicking the checkbox at the top.