Presseinformationen der Lenze-Gruppe

26. November 2025

Lenze erhält IEC 62443-4-1-Zertifizierung: TÜV Rheinland bestätigt cybersicheren Entwicklungsprozess

25. November 2025

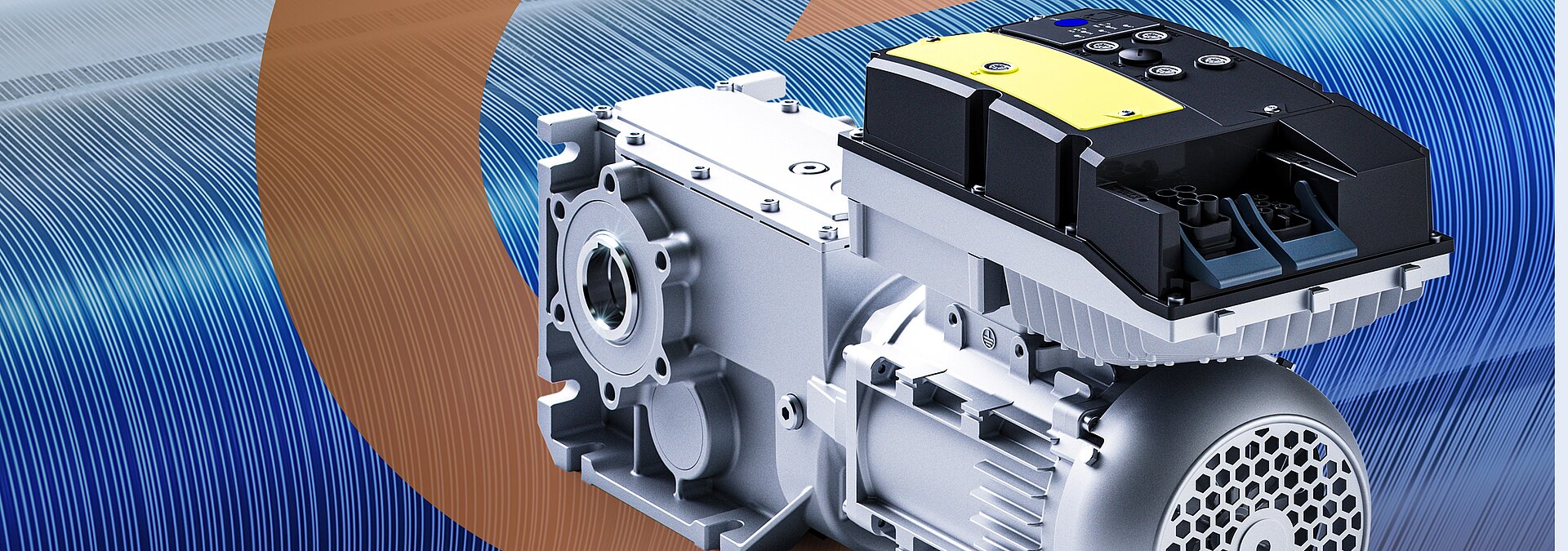

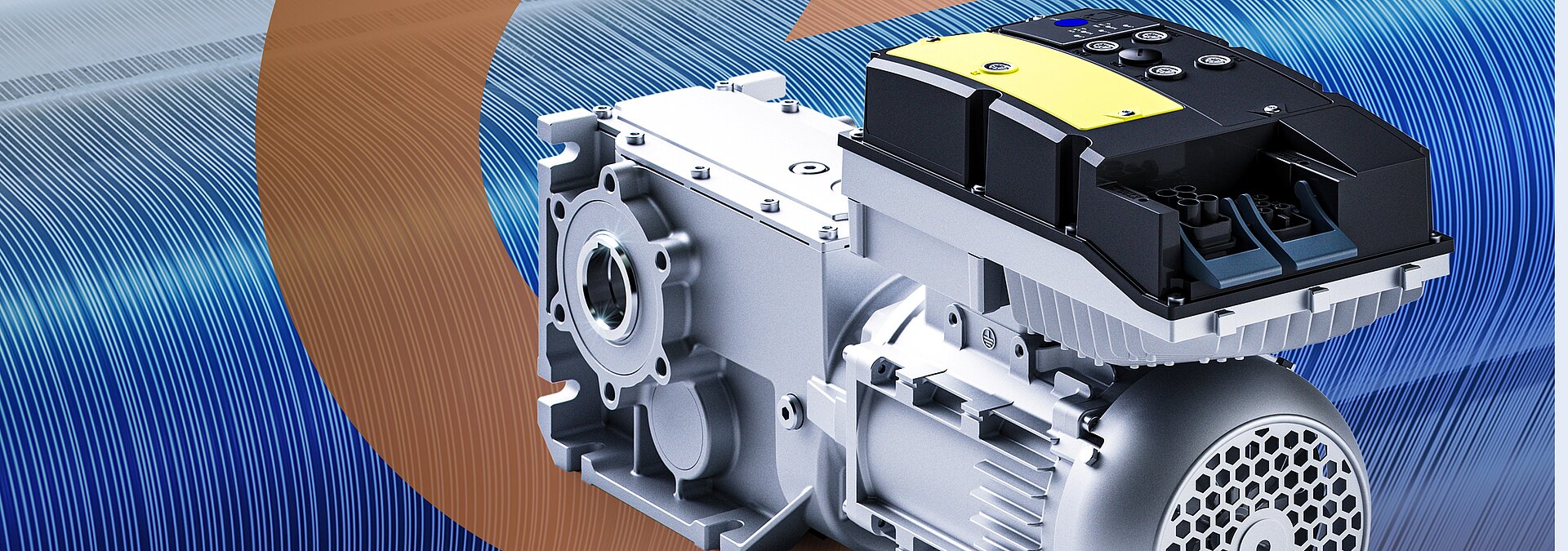

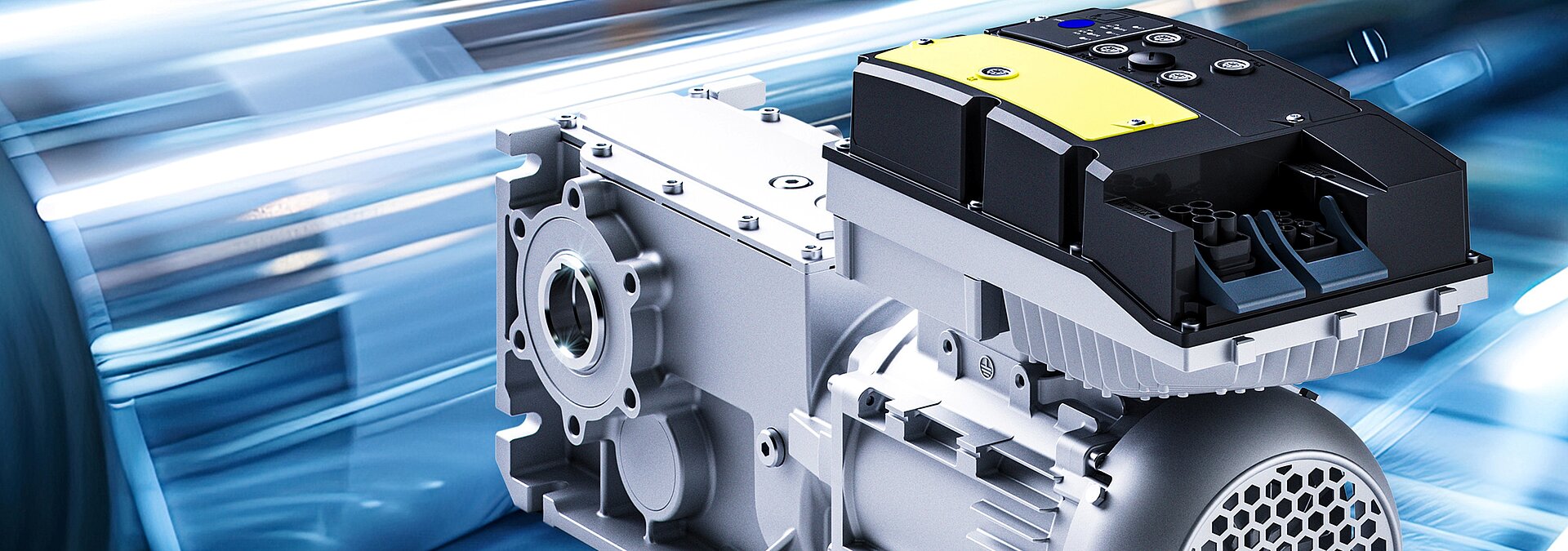

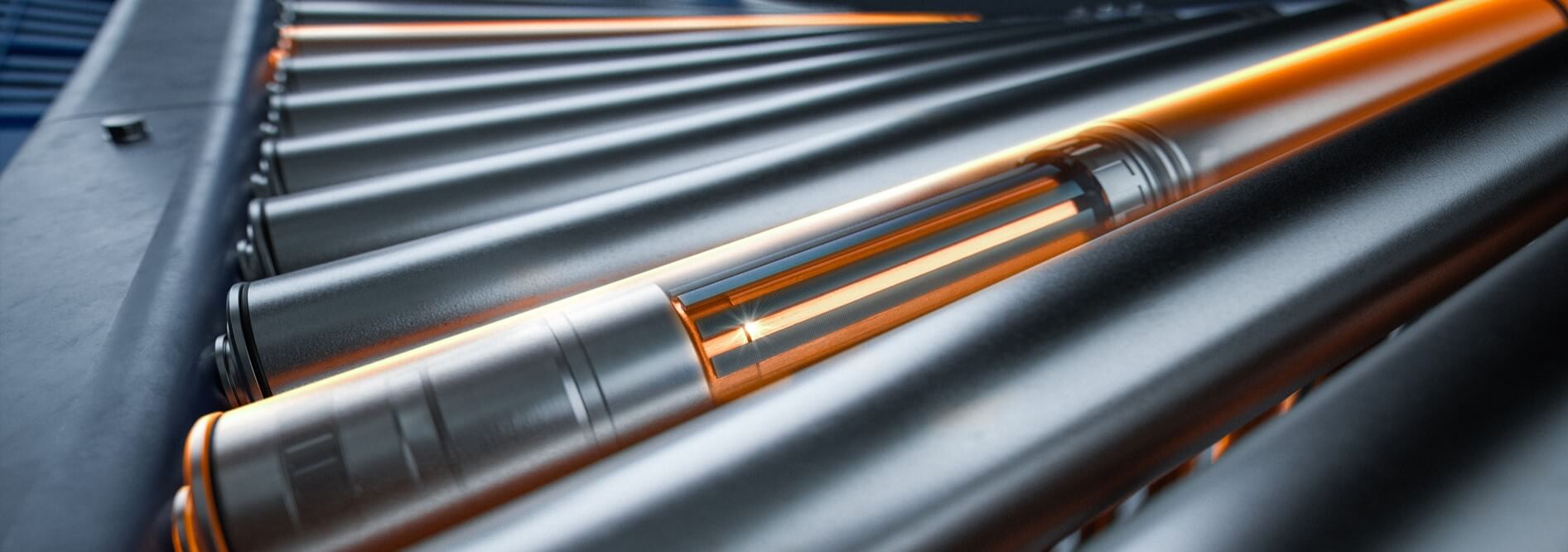

Von null auf hundert: Das IE5/IE6 Motor Drive System mit i650 motec setzt neue Standards in Sachen Performance und Effizienz

28. Oktober 2025

Innovationen für nachhaltige Textilproduktion: Lenze präsentiert auf der ITMA Asia das Motor Drive System IE5/IE6

14. Oktober 2025

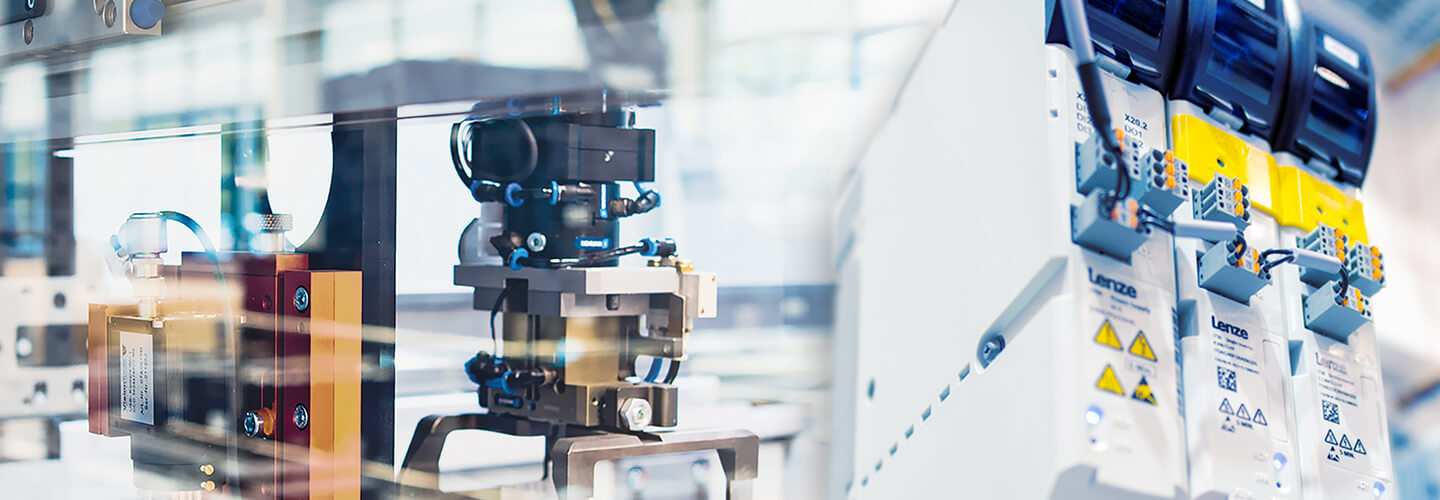

Lenze auf der SPS 2025: Effizienz und Flexibilität für die nächste Maschinengeneration

01. Oktober 2025

Lenze auf der ITMA Asia 2025: Smartes, robustes und kosteneffizientes Motor Drive System IE5/IE6 für die textile Zukunft

16. September 2025

Von null auf hundert: Das IE5/IE6 Motor Drive System mit i650 motec setzt neue Standards in Sachen Performance und Effizienz

09. September 2025

Familienunternehmen Lenze: Eigentümerfamilie übernimmt operative Verantwortung

28. August 2025

Lenze auf der Labelexpo Europe: Skalierbare Antriebstechnik und durchgängige Automatisierung für die Printing und Converting-Industrie

06. August 2025

Lenze Gruppe stellt Vorstand neu auf – Fokus auf Transformation und Zukunftsfähigkeit

12. November 2024

Energieeffizient, einfach und kompakt – das neue Motor Drive System IE5/IE7

12. November 2024

Markus Sandhöfner startet als Group Vice President Global Accounts / Frank Lorch übernimmt die Leitung des Kundenservice

16. Oktober 2024

Veränderungen im Lenze-Vorstand: Dr. Marc Wucherer wird zum 1. Januar 2025 neuer Vorstandsvorsitzender

18. September 2024

Digital Hub Industry Bremen ab sofort Teil der de:hub-Initiative der Bundesregierung

13. September 2024

Dr. Johannes Haupt wird neuer Aufsichtsratsvorsitzender der Lenze SE

31. Juli 2024

Lenze setzt auf erneuerbare Energien – neue Photovoltaikanlage bringt 3,7 Gigawattstunden pro Jahr

28. Mai 2024

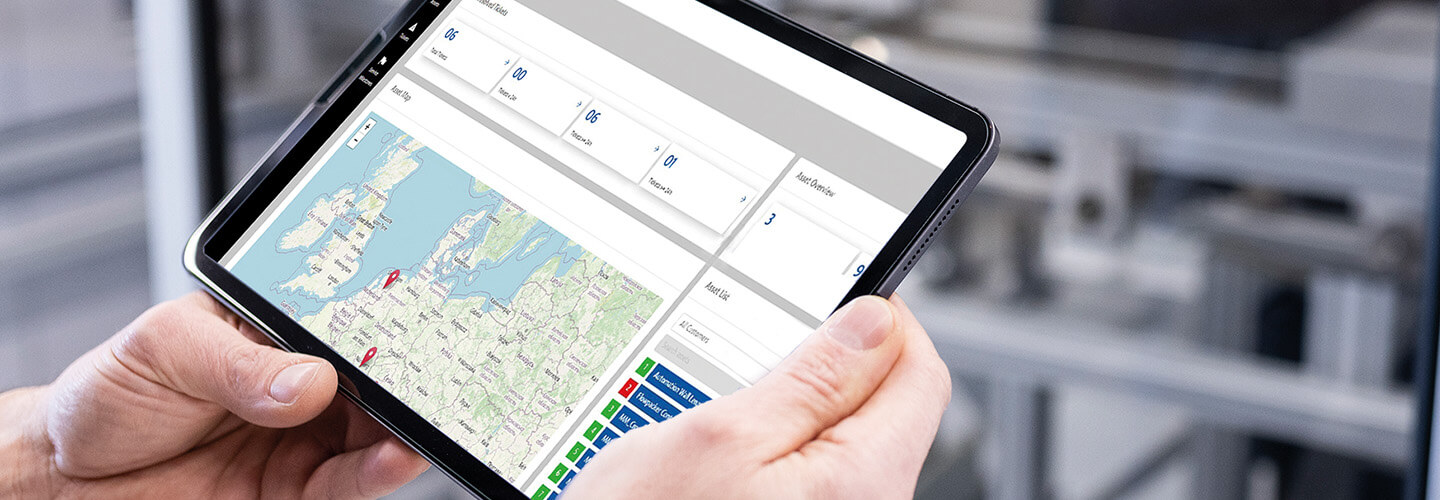

Das Digitalisierungspotenzial ausschöpfen – Lenze präsentiert innovative Lösungen auf der Drupa

01. August 2023

Die Zukunft im Blick - 38 Nachwuchskräfte starten bei Lenze ins Berufsleben

25. Mai 2023

Lenze bringt Antriebsperformance mit Servoumrichter i750 auf das nächste Level

4. Mai 2023

Lenze liefert das Komplettpaket für die Automatisierung der Verpackungsindustrie

Messestand auf der Interpack überzeugt mit cloudbasierten Portallösungen und Live-Präsentationen

28. April 2023

Neugierig auf Technik

Zukunftstag: 50 Schülerinnen und Schüler erleben Lenze hautnah

16. April 2023

Der Maschinenbau braucht digitale Lösungen

Lenze zeigt, wie das Zusammenspiel von IT und OT Maschinenbauer wettbewerbsfähiger macht

23. März 2023

Neuer Chief Technology Officer (CTO) für die Lenze-Gruppe

Dr.-Ing. Claus Bischoff tritt im April die Nachfolge von Dipl.-Ing. Frank Maier an

15. Oktober 2022

Mechatronic Competence Campus (MCC) in Extertal eröffnet

Mitarbeiter und ihre Familien feiern 75 Jahre Lenze in Groß Berkel und weltweit

13. Oktober 2022