Efficient, precise, dynamic

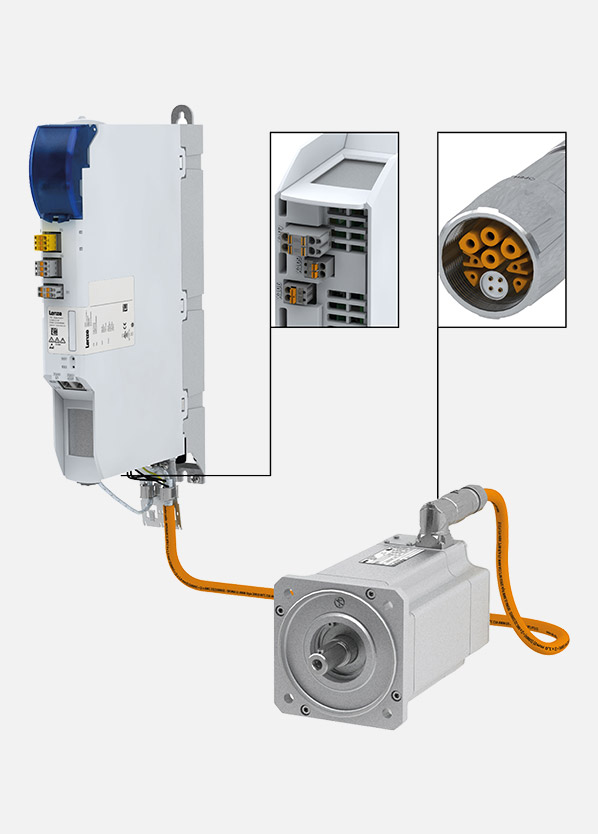

Fast response times, absolute movement accuracy, intelligent algorithms, and maximum productivity are the basic requirement for competitive machine automation. With over 75 years of experience in drive technology, Lenze understands these challenges and is offering a powerful solution for motion control applications with its i750 multi-axis servo drives.

The full potential of the i750 becomes apparent when it is used in conjunction with our Lenze controllers, making it an indispensable element in sophisticated automation systems. Users benefit from maximum precision and a high throughput.

The new standard for controller-based motion

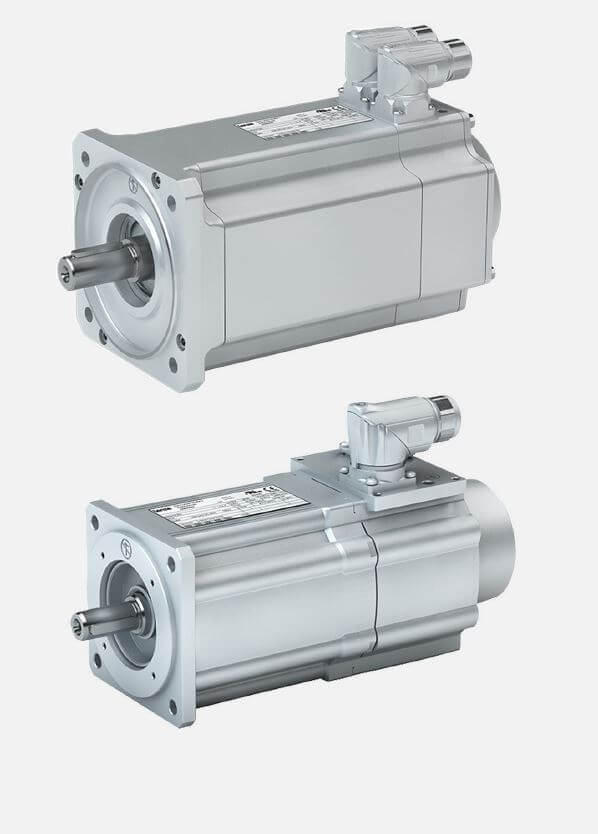

The i750 cabinet, when used in combination with modern Lenze controllers, tackles practically all

automation tasks for dynamic multi-axis applications. The product range consists of power supply

modules and single and double axes operated in the DC configuration. Key features are a narrow

installation width and extensive integrated safety technology.