In connection with absolute position feedbacks (resolvers, singleturn and multiturn SinCos absolute encoders) can optionally functions for position reconstruction used .

These functions enable it to restore the correct actual position with the restart of the device/machine, and namely taking into account taking the resulting position offset by any movements done in off state. Using this function, specific position data must be stored in the inverter / controller during the power down (retain data).

There are two reconstruction functions to distinguish between:

- Encoder position reconstruction in device (firmware of the servo inverter i750 + i950;

function per default enabled (recommended), can be deactivated via 0x2DE0:028 Bit0) - Machine position reconstruction in the superimposed control (MotionAxis)

(function can be activated via subindex :081)

Common advantages of these features:

- Expansion of the usable positioning range of the application, via the absolute display range of the used absolute encoder used, which is usually set to a to 4096 encoder revolutions.

- The absolute encoder can be mounted on the machine with any encoder value and in any mechanical position.

During commissioning, the display range of the encoder does not have to be laboriously adjusted to the mechanical travel range in order to avoid overflow.

Advantage and Application of encoder position reconstruction in device (firmware):

- In topologies with a third-party motion controller, the reconstructed position is provided to the superimposed motion software.

- i950 extended safety: The 'mini homing' function can also be used with single-turn absolute encoders or resolvers.

Explanation of the function of encoder position reconstruction using two examples

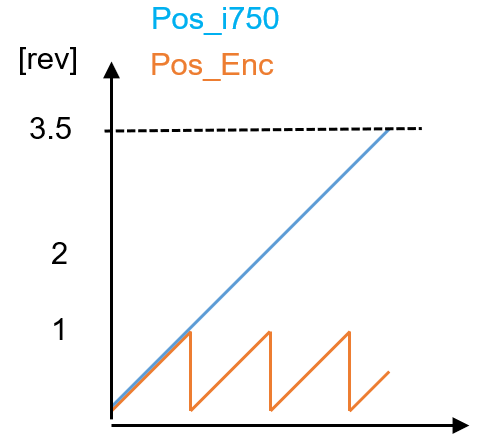

Example 1 (single-turn absolute encoder):

Sequence:

- Single-turn absolute encoder with active encoder evaluation (control card powered) rotated by

3.3 revolutions, i.e. three times beyond its display range. - Then switch off the device and, while it is switched off, move it a further 0.2 revolutions.

- Switch the device back on. The actual position is reconstructed.

Result

- The encoder position reconstruction causes the actual position to be initialized correctly with 3.5 revolutions.

The value corresponds to the last actual position when the device was switched off plus the additional offset that occurred in the switched-off state.

- Without encoder position reconstruction, the actual position would only have been initialized with 0.5 revolutions, i.e., the (modulo) value within the absolute display range of the encoder (red curve). All distances traveled outside the encoder display range would be lost, keyword: overflow.

Example 2 (multiturn absolute encoder):

Procedure:

- Switch on the servo inverter immediately after mounting the motor with a multiturn absolute encoder, e.g. an AM128:

Actual position = 1.0 revolution. Then m

In order for the encoder position reconstruction to be possible, the last valid position value must be stored (persisted) in the device in a manner that is secure against power failures when the servo inverter is switched off.

This means that the reconstruction can only be accurate if it is performed on the same servo inverter on which it was persisted.

ove the encoder two revolutions in the negative direction (CCW) to the reference position.

The encoder is thus turned in the CCW direction beyond its absolute display range.

- Switch on the power to the servo inverter and reinitialize the actual position.

Result:

- With and without encoder position reconstruction, the initialized actual position (current position 0x6064) is different:

| Encoder position reconstruction

(0x2DE0:028 Bit0) |

| Active

Bit0 = FALSE (Default) | Inactive

Bit0 = TRUE |

Current position (0x6064) BEFORE switching on the power | minus

1 turn. | minus

1 turn. |

Current position (0x6064) AFTER power-up | minus

1 turn. | plus

4095 Turn.

|

This the encoder position reconstruction possible , the when switching off the servo converter the last valid position value in device battery-backed stored (persistent) . The means that that the reconstruction only fit if if it on the same servo converter , on the also persisted.

In order for encoder position reconstruction to be possible, the last valid position value must be stored (persisted) in the device in a power failure-proof manner when the servo inverter is switched off.

This means that reconstruction can only be accurate if it is performed on the same servo inverter on which it was persisted.

Usage of the 'encoder position reconstruction in the base firmware' feature

A major advantage of encoder position reconstruction is that no initial position needs to be taken into account when mounting the encoder, which would be necessary if this were the only way to prevent an overflow in the encoder's display range during operation and also in the event of unexpected coasting.

When using the i750 + i950 servo inverters with Lenze MotionControl, whether in the axis itself or in a Lenze controller, referencing and machine position reconstruction take place in the application (Motion).

The selection of the encoder position reconstruction (0x2DE0_28 Bit0) can be arbitrary in all these cases; there is therefore no reason to change the default (0x2DE0_28 Bit0 = FALSE).

When using the i750 / i950 base and i950 TA CiA402 Advanced with a third-party motion controller AND position encoders with absolute information, the application software developer decides whether encoder position reconstruction should remain activated in the base firmware, depending on the application requirements.

Here, the encoder position reconstruction can also remain activated if

- the absolute position information of the motor encoder is not relevant for the motion.

For example, the absolute value encoder is only required for the pole position information, or no position control or monitoring is used at all. - if the current position 0x6064:0 corresponds to the real encoder position without calculated offset.

0x6064 no longer corresponds to the real encoder position and, if

If, in this case, re-referencing after replacing the servo inverter is not possible or not desired, then the encoder position reconstruction must be deactivated (0x2DE0_28 Bit0 = TRUE).

This will then store retain data in the i750/i950 base unit.

In this case, it must be ensured that the servo inverter is re-referenced when it is replaced at a later date. This can be monitored, for example, in the higher-level control system by reading and comparing the serial number of the servo inverter. If this individual serial number has changed from the value stored during referencing, then referencing must be performed again.

If you do not use encoder position reconstruction (Bit0 = TRUE), you must ensure that the encoder display range is not exceeded. In individual cases, this may mean that an encoder must be aligned to a starting position before installation in the machine kinematics.

Tips:

Check whether 0x6064:0 corresponds to the actual encoder position without calculated offset.

- For the resolver

The value displayed online in actual position rotor angle 0x2DDE:0 multiplied by 32 must correspond to the value from actual position 0x6064:0 (with a few increments tolerance + at default 0x608F:1 = 16 bits). - For the Hiperface absolute encoder

The value displayed online in Motor encoder settings (HIPERFACE): Actual position (raw data) 0x2C41:6 multiplied by k must correspond to the value from Actual position 0x6064:0 (with a few increments tolerance + at default 0x608F:1 = 16 bits).

Encoder

Typ | Auflösung

0x2C41:6 | k |

AM1024 | 15 Bit | 2 |

AM512 | 14 Bit | 4 |

AM128 | 12 Bit | 16

|

Deleting inappropriate reconstruction information

To ensure that no inappropriate reconstruction information is stored in the base unit of servo converters that are not brand new, this information can be deleted by executing the axis command “Reset position to native value” (0x2822: 40 or 41). This transfers the raw position of the connected absolute encoder to 0x6064 and sets stored offsets to zero.