Function:

Function: When the safety function is requested, the motor is decelerated to safely limited speed (SLS3) (black characteristic).

If decelerating fails without ramp monitoring, the excessive speed will only be detected after the braking time of SLS3 (red characteristic).

With ramp monitoring, the fault will be detected by the monitoring of safely limited speed SLS1 and SLS2. In this way, the parameterised error response (in the example STO) can be activated (blue characteristic) before the braking time of SLS3 is over.

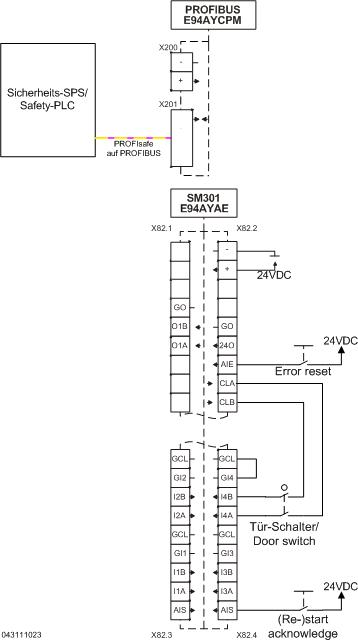

The safely limited speeds are switched by the PLC. The braking times are implemented in the SM301.

SLS1 is activated and after 1.5 s monitored with 3000 rpm. If the current speed is lower than the SLS1 threshold, 'SLS1 observed = 1' will be set in the SM301. This activates SLS2. After 1 s, SLS2 will be monitored with 2000 rpm. If the current speed is lower than the SLS2 threshold, 'SLS2 observed = 1' will be set in the SM301. This activates SLS3. After 1 s, SLS3 will be monitored with 1000 rpm.

Safety information / disclaimer:

The safety application and parameterisation notes are examples of possible subfunctions in machines.The T10D value according to DIN EN ISO 13849-1, Annex C.4.2 is only indicated if a B10D value is available and the operating time is less than 20 years. Commissioning is prohibited until the machine has been checked in accordance with the regulations set out in the relevant EU directives / national laws. The safety instructions contained in the technical documentation must be observed. Using the examples does not exempt the user from careful project planning. For possible damages and consequential damages Lenze assumes no liability to the extent permitted by law. Copyright 2019 Lenze Automation GmbH