Eliminated from:

9400 HighLine SW V05.00.30.00

Behaviour of the new version?

The supply voltage of the PTC evaluation was not generated until the LU status had been exited and was not stable after another approx. 100 ms. When LU was exited, however, the PTC evaluation was activated immediately. Since a stable supply voltage was not available, the error signal was generated.

With the new version, the PTC evaluation is delayed by another 500 ms after the LU status has been exited to ensure a stable supply voltage of the PTC evaluation.

<hr>

Which products are affected?

9400 HighLine SW ≤ V04.01.00.00, from size 8 onwards (rated currents 145A and higher)

What happens?

After connection of the power supply, the drive indicates a motor overtemperature error (activation through motor PTC, error number C0168 = 0x0077000f).

When does the problem occur?

The problem only occurs with 9400 HighLine drives as of size 8 (rated output currents >= 145A) when the power supply is connected and a motor PTC is connected via terminals T1 and T2. The PTC evaluation electronics is supplied via the DC bus. When the DC-bus voltage is built up, the overtemperature error is activated erroneously through initialisation processes in the PTC evaluation.

Possible diagnostics?

After connection of the mains supply (charging the DC bus), the controller indicates a motor overtemperature error (C0168 = 0x0077000f).

Short-term measures/recommendations?

Since the output stages are inhibited when a DC-bus undervoltage occurs and the motor windings are, accordingly, not energised, a motor overtemperature error can actually not occur during this phase and - as a result - neither directly after connection of the mains supply.

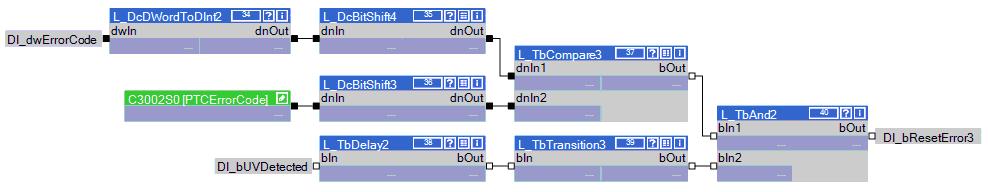

With an appropriate addition in the function block interconnection of the 9400 HighLine, a motor overtemperature error can - under these circumstances - be reset automatically. Below you can find a suggestion for an addition to the function block interconnection.

L_DcDWordToDInt2: converts the number of the current fault from the numerical DWORD format into the numerical DINT format

L_DcBitShift4: removes the six most significant bits of the error code (error response, instance ID) from the 32-bit display area because they are not important for the error evaluation

User code C3002: contains the error number for the motor overtemperature detection via terminals T1/T2 (8060943 = 0x007b000f)

L_DcBitShift3: removes the six most significant bits of the comparison value (error response, instance ID) from the 32-bit display area because they are not important for the error evaluation

L_TbCompare3: compares the current error number with the error number for motor overtemperature

L_TbDelay2: OFF-delay of undervoltage message by 500ms

L_TbTransition3: sets a 1ms-pulse on the falling input edge which is output as auto-trip-reset command via

L_TbAnd2 at

DI_bTripReset3 when the motor overtemperature error is active.

L_TbAnd2: switches the auto-trip-reset command only through to

DI_bTripReset3 when a motor overtemperature error (

L_TbCompare3.bOut = TRUE) has been detected up to 500ms after connection of the power supply (

L_TbDelay2.bOut = TRUE => FALSE).

Evaluation:

The error only occurs with devices as of size 8 (rated output current >= 145A).

When the motor overtemperature error has occurred as a result of the described function restriction, the error status can be reset via the specified automatism.

Published with Service Message No. 47/2008