Lenze at LogiMAT from March 24-26, 2026, in Stuttgart

Experience intelligent drive and automation solutions for your intralogistics applications

Shape the future of your material flow – efficiently, safely, and flexibly

Experience how passion and innovation take your intralogistics to the next level:

Reduce energy consumption – with energy-optimized drive components.

Counteract the shortage of skilled workers – with automation and easily integrable systems.

Shorten time-to-market – thanks to smart engineering tools and fast commissioning.

With a passion for logistics automation, we work with you to design the solutions of today and tomorrow.

We look forward to talking to you in person!

Your requirements, our solution: Motion technologies for every strategy

Optimize your storage and retrieval machines with innovative motion solutions from Lenze.

Whether Controller Based Motion or Drive Based Motion, we offer the right strategy for maximum efficiency and flexibility.

Controller Based Motion– maximum customization

- Tailor-made solutions for complex storage and retrieval machines

- Adjustments made directly in the PLC for maximum flexibility

- Engineering effort significantly reduced thanks to Lenze FAST Application Software

Drive Based Motion– fast and standardized

- Simple parameterization with the EASY Starter

- High degree of standardization for fast implementation

- Reduced system costs thanks to axis-integrated PLC functionality

- Commissioning time reduced by approx. 30%

Benefit from shorter project times, reduced costs, and maximum operational reliability.

Prepared Lenze FAST software blocks for the "shelving machine solution".

- Compatible with all common travel and hoist concepts

- Suitable for use in normal operation and in deep-freeze areas

- Includes comprehensive safety technology

The focus is on the i950 multi drive – the next evolutionary stage for modular drive systems in storage and retrieval machines. Thanks to the integrated DC rail system, high power density, and flexible architecture, it significantly reduces wiring requirements and enables a more compact control cabinet design.

The result: maximum performance with minimum space requirements – perfect for modern, energy-efficient warehouse solutions.

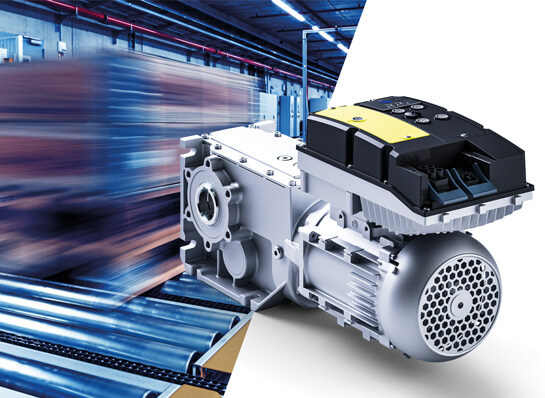

Powerful energy source for horizontal conveyor technology – Motor Drive System in IE5/IE6

Energy-efficient combination of motor, gearbox, and frequency drives.

The system can be combined with any converter from our portfolio, offering impressive versatility. This powerhouse really comes into its own in highly dynamic applications:

More power when needed

300% overload torque from standstill to meet high acceleration requirements and sudden load peaks.

Space requirements

No increase in size despite increased energy efficiency – ideal for machines with limited installation space.

Increased efficiency

Optimized control algorithms and an improved motor design reduce losses and lower energy consumption.

Decentralized, efficient, flexible – horizontal conveyor technology reimagined with the i650 motec

The decentralized i650 motec frequency drive (motor- or wall-mounted) helps you master current and future challenges:

Reduction of installation costs and time

Cascading converters reduces cable runs, plug-in technology, and integrated I/O systems reduce installation time and additional components.

Increase flexibility and reduce variance

Conveyor lines can be easily expanded or converted. The integrated Logic PLC replaces the control cabinet and enables compact, scalable solutions.

Increasing energy efficiency and reducing operating costs

The integrated regeneration of braking energy increases efficiency, while the latest motor control with our IE5/IE6 improves overall energy consumption.

Reduction of production downtime in the event of a fault

Fault detection and service are performed without access to central controls – thanks to the extension box with repair switch, optional overload/short-circuit protection, and operating elements.

How a DC system takes (intra)logistics to the next level

DC systems are considered a key technology for greater energy efficiency, sustainability, and security of supply.

They open up new possibilities, particularly in logistics: from efficient energy distribution to the direct integration of renewable energies and storage solutions.

An introductory keynote speech and subsequent panel discussion will show how DC can revolutionize energy use.

Experts from industry and research will discuss the standards, applications, and scenarios that arise from the use of DC systems and how companies are already benefiting from them today.

Join us live as our expert Dr. Marian Köller takes you on a journey into the world of the DC industry.

March 25 from 10:10 a.m. to 11 a.m.

Messe Stuttgart, Expert Forum, ICS C1

And don't Drink without Drive

Visit us from March 24–26, 2026, at LogiMAT in Stuttgart in Hall 5, Booth D67!

On Tuesday, March 24, and Wednesday, March 25, we cordially invite you to a cozy get-together at our booth starting at 4 p.m.

Enjoy a cool drink and fresh pretzels – the perfect opportunity to chat in a relaxed atmosphere, discuss new approaches, and make new contacts!