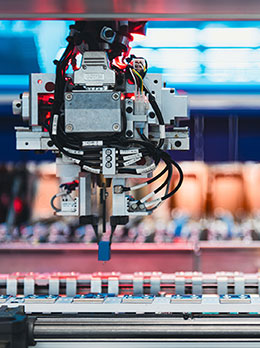

Condition Monitoring

Delivers real-time condition monitoring

When the drive becomes a sensor: We are illustrating how smart Condition Monitoring can be realised that provides extensive information about the "state of health" of machines and plants without the need for any additional, costly sensor technology.

Collecting and interpreting the available data is already a sound way of monitoring the condition of machines. This requires a deeper understanding of the machines and processes so as to generate meaningful information from the "bare" data. Analyses based on Machine Learning (ML) and AI can help identify anomalies faster. In this showcase we show this and visualize the evaluation result with the help of a digital twin:

Two options for optimal results

Model-based approach: Here the measured actual values are compared with those resulting from the assumed mathematical/physical description of the machine. If certain patterns are detected or tolerances are exceeded, this is interpreted as an anomaly.

Data-based approach. A machine learning algorithm learns the normal state of the system based on the measured data, for example motor speed, acceleration, torque, position and current consumption. The real values are compared with this learned description to detect deviations.

Here the data is evaluated

The two Condition Monitoring approaches differ not only in terms of their concept. The question as to how this data is evaluated also has different answers. The model-based evaluation usually takes place on the control system because it does not require any significant computing power. ML and AI analyses used for data-based evaluations are normally implemented as a Cloud application.

Lenze's portfolio gives the OEM complete freedom of choice. This includes a number of different three-dimensional PLCs for model-based Condition Monitoring. A route to the Cloud can be provided using the x500 gateway. Combined with the x4 platform, mechanical engineers have a turnkey Cloud solution that covers not only Condition Monitoring but also remote maintenance for the machine and user-friendly Asset Management.

Learn more about Lenzes Digital Solutions.

Simply use existing sources

The trick with this solution is to extract the added information value from data sources that are already available. No additional sensors are needed Lenze provides pre-tested algorithms for various applications and helps mechanical engineers turn their process expertise and knowledge of machines into a Condition Monitoring model that will improve efficiency.