Question:

Servo inverter i950 and operation of "simple" asynchronous motors (ASM) in servo control:

What measures are recommended to dampen the vibrations that occur with some types of motor?

Answer:

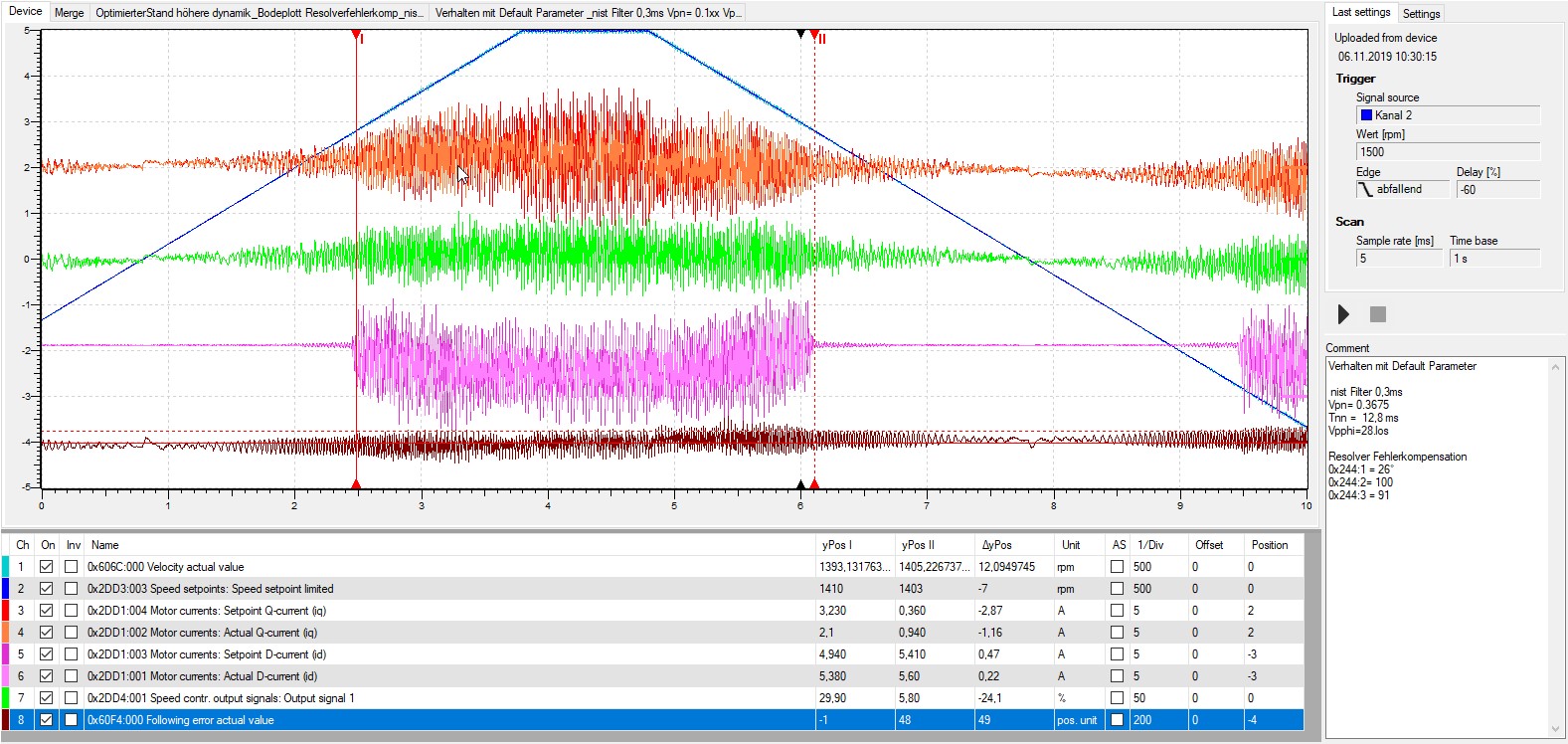

When operating ASM with feedback system in servo control, increased vibrations (ripple) can occur in the current/torque and speed curves at high speeds, especially in the field weakening range. This behaviour is particularly noticeable with standard asynchronous motors, which are only optionally equipped with an encoder:

Vibrations at high speeds are mainly excited via the feedback system and have primarily mechanical causes. Two decisive aspects:

- How precisely and rigidly is the feedback system mounted on the motor shaft?

- How rigid and low-vibration is the associated torque support?

With some motor types, these aspects cannot be implemented as optimally as with original servo motor types due to design conditions.

The following short-term remedial measures are recommended:

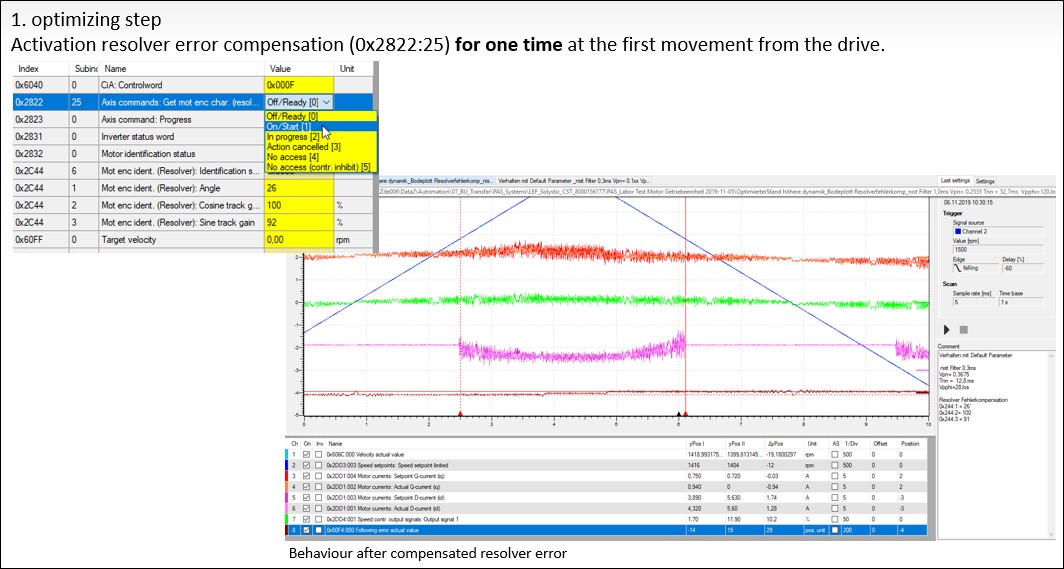

Execute commissioning function "Identify resolver compensation" (0x2822:25):

The oscillations are significantly reduced because the function can compensate a part of the excitation frequencies:

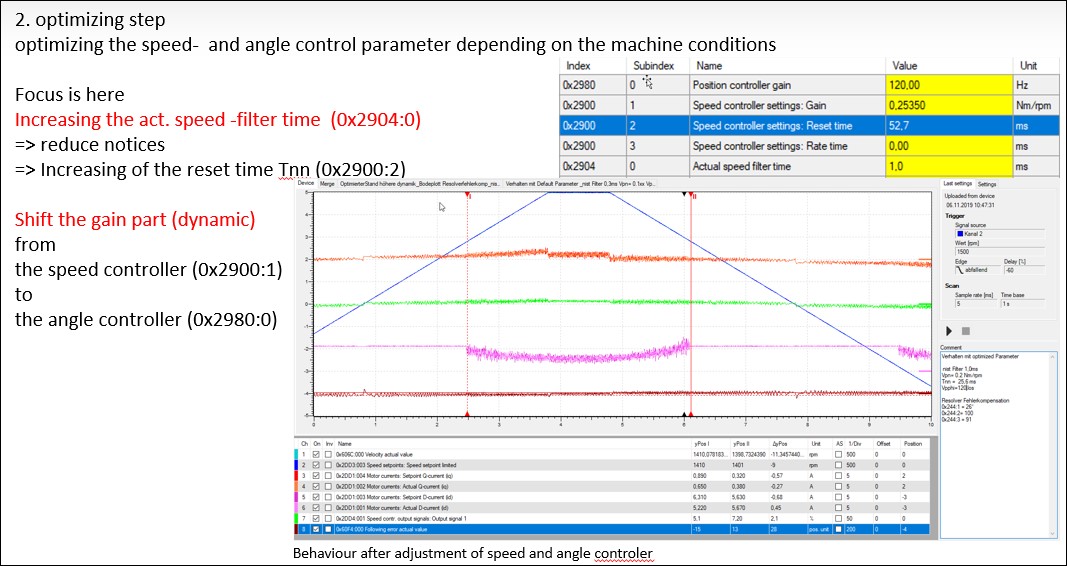

Adjust controller settings

- Speed actual value filter: filter more strongly, i.e. increase time constant (0x2904) and

- Set the speed controller weaker,

- i.e. reduce speed controller gain Vpn (0x2900:1) and

- Increase speed controller reset time Tnn (0x2900:2).

- To do this, set the position controller tighter, i.e. increase the position controller gain Vpp (0x2980).

As a result the oscillations can be reduced even further:

Automatic Translation