Function:

Function:

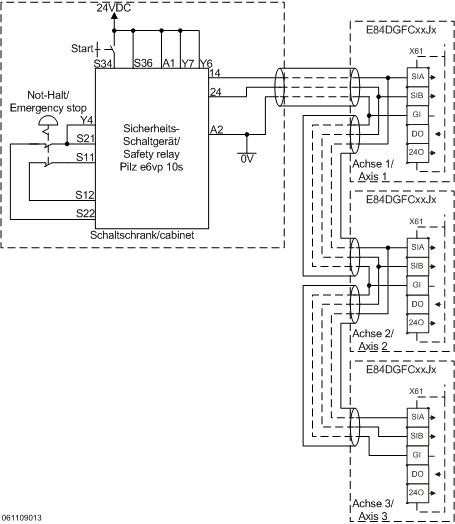

When the safety function is requested, the motors are switched off according to stop category 0 of EN 60204-1.

Faults have been excluded for protected cables (according to DIN EN ISO 13849-2:2003-12 and IEC 61800-5-2:2007-07). This applies to cables which are protected by a cable duct and installed inside the control cabinet.

Assumption: In the example, it is not possible to exclude mechanical faults for the cables between the control cabinet and the 8400 motecs.

Cross-connections that may occur here result in the safe state.

Due to the input capacitances of approx. 3 nF per channel and controller, the clock pulses of the OSSD outputs of the safety relay will be rounded.

Of course, the capacitances of the cables still have to be added.

If additional controllers are connected, the pulses will be rounded even further.

With more than three axes, the pulses may already have been rounded that much that the voltage interruption during the clock pulse will no longer be properly detected by the safety relay.

Operation is no longer possible because the safety relay will interpret this as a short circuit or cross-connection of the safe outputs and switch off the outputs.

By using discharge resistors at the OSSD outputs, the capacitances can be discharged during the clock pulses. In this way, the clock pulses will again be more clearly identified by the safety relay.

If it can be assumed that faults can be excluded for the cables between the safety relay and the controllers, it is also possible to decouple the capacitances by series connections with diodes at the safe outputs 14 and 24 from the OSSD outputs.

Since it is not assumed in the example that faults can be excluded, decoupling by diodes should not be used here because otherwise the cables can no longer be monitored for short circuits and cross-connections.

Safety information / disclaimer:

The safety application and parameterisation notes are examples of possible subfunctions in machines.The T10D value according to DIN EN ISO 13849-1, Annex C.4.2 is only indicated if a B10D value is available and the operating time is less than 20 years. Commissioning is prohibited until the machine has been checked in accordance with the regulations set out in the relevant EU directives / national laws. The safety instructions contained in the technical documentation must be observed. Using the examples does not exempt the user from careful project planning. For possible damages and consequential damages Lenze assumes no liability to the extent permitted by law. Copyright 2019 Lenze Drives GmbH