Function:

Function:

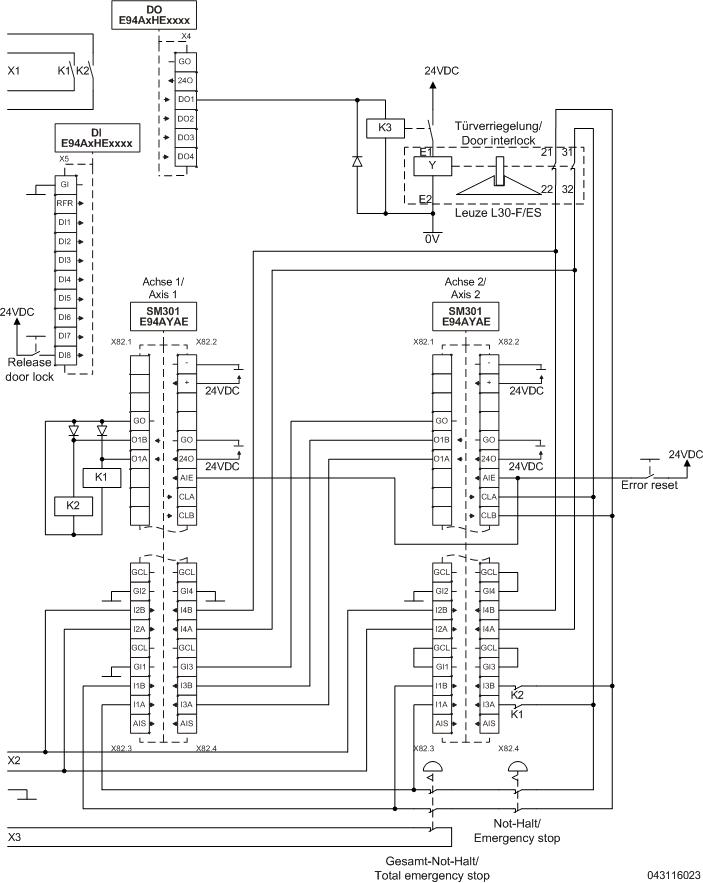

Sensors may be connected to more than one axis.

In the example, there is a 'total emergency-stop' button that shuts down both axes and, using an additional contact (X3), shuts down a function outside the machine part under consideration through one channel. The 'emergency-stop' button only switches off the machine part under consideration.

The restart inhibit is implemented in the machine part that is not under consideration.

The machine part not under consideration safely gets the status 'both SM301s free from errors' and 'both emergency-stop buttons not actuated' via the floating contacts X1.

K1 and K2 must be positively driven relays (e. g. Wago 788-384). To check if the relays work correctly, the feedback contact must be connected to a safe input of the SM301 (SD-In3 of axis 2). Then, the discrepancy time of the two relays is monitored via the safe input.

In the case of errors in other machine parts, the safety control system (not looked at) can safely switch off the two safety modules via X2.

It is possible to open the safety door locking by means of a non-safe output of the basic device and to have the status evaluated by the safety module. In this way, you can use the safe output of the SM301 for additional functions.

In the example, traversing at safely limited speed is required when the safety door is open.

If the pushbutton for opening the door lock is actuated, the door lock will be open for 2 s (if the current speed is lower than C00019). In this time, the door must be opened.