Lenze has been convincing customers for more than 15 years with a deep understanding of their specific requirements, a universal and scalable automation portfolio, and has the right feel for machine builders on their way to the smart factory. From experience, Lenze knows that the basis of a long-term collaboration is to understand the diverse application areas of its customers.

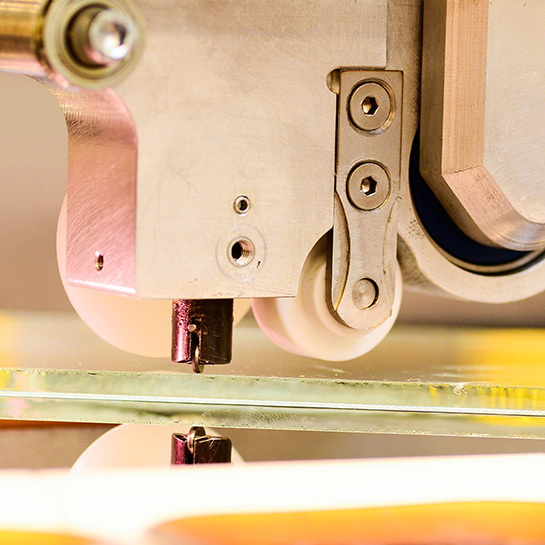

Taking a closer look, Lenze drives and automation solutions are used in almost all LiSEC glass processing plants to realize the diversity in the glass world. From warehouse, into the glass cut, right up to the finished insulating glass pane, a number of machines and work steps are necessary in which Lenze is involved everywhere.

About the company LiSEC:

LiSEC Austria GmbH is one of the world's largest suppliers in the field of flat glass processing and finishing. LiSEC's versatile machines have been used, among other things, to produce the facade elements for the Google headquarters in California or the world's tallest building, the Burj Khalifa in Dubai.

Scalable solutions that grow with you

From a technical point of view, it is enormously important for LiSEC that Lenze's products and systems grow with the automation tasks and remain compatible across the different machine generations. The i550 series of variable frequency drives has proven itself in this regard, and impresses along the entire "glass" line with its scalable functionality and compact design. Werner Holzknecht, Head of Automation Services at LiSEC, is satisfied and looks back over the last few years: "The Lenze drive has been able to cope with all our change requirements over the last few decades, regardless of whether the bus system or the range of functions has changed, torque control was required, a system migration was necessary or - the best example - we wanted to control a synchronous motor without sensors. The universal Lenze drive is also ideal in terms of size. With all this flexibility, it is still not an isolated solution, but a standardized and standardized component with all the advantages of industrial production and quality assurance."

LiSEC’s goal

Using smart solutions to leverage both the explicit and implicit information in this data, thereby generating an increase in quality, efficiency, transparency, flexibility and added value.

Common goal - clear focus

The continuous development and expansion of decentralized supply units, as well as the introduction of drive technology without control cabinets. Furthermore, there is an unchanged focus on decentralized intelligence in drive technology, predictive and preventive maintenance and a noticeable improvement in the area of commissioning through automatic teach-in. The relevant topics of One Cable Technology (OCT) and bus systems with safety functions (FSoE) will also not be neglected.

“It distinguishes us to focus on the overall system and thus offer an optimal total package from motor, gearbox, drive, to the right controller and remote maintenance concept."

“It distinguishes us to focus on the overall system and thus offer an optimal total package from motor, gearbox, drive, to the right controller and remote maintenance concept."