Energy efficiency, flexibility and ease of use are common requirements which can be maximized by using the right drives. Whether for decentralized applications or in a cabinet Lenze offers a wide portfolio of variable frequency drives and servo drives which provide the same user-friendly handling. The key to the success of your application ultimately lies in the details of the performance and drive concept.

Lenze drives: the perfect fit to your application

Whether you want to equip pumps, HVAC applications, machines, warehouses or entire production lines, with Lenze you get the drive you need.

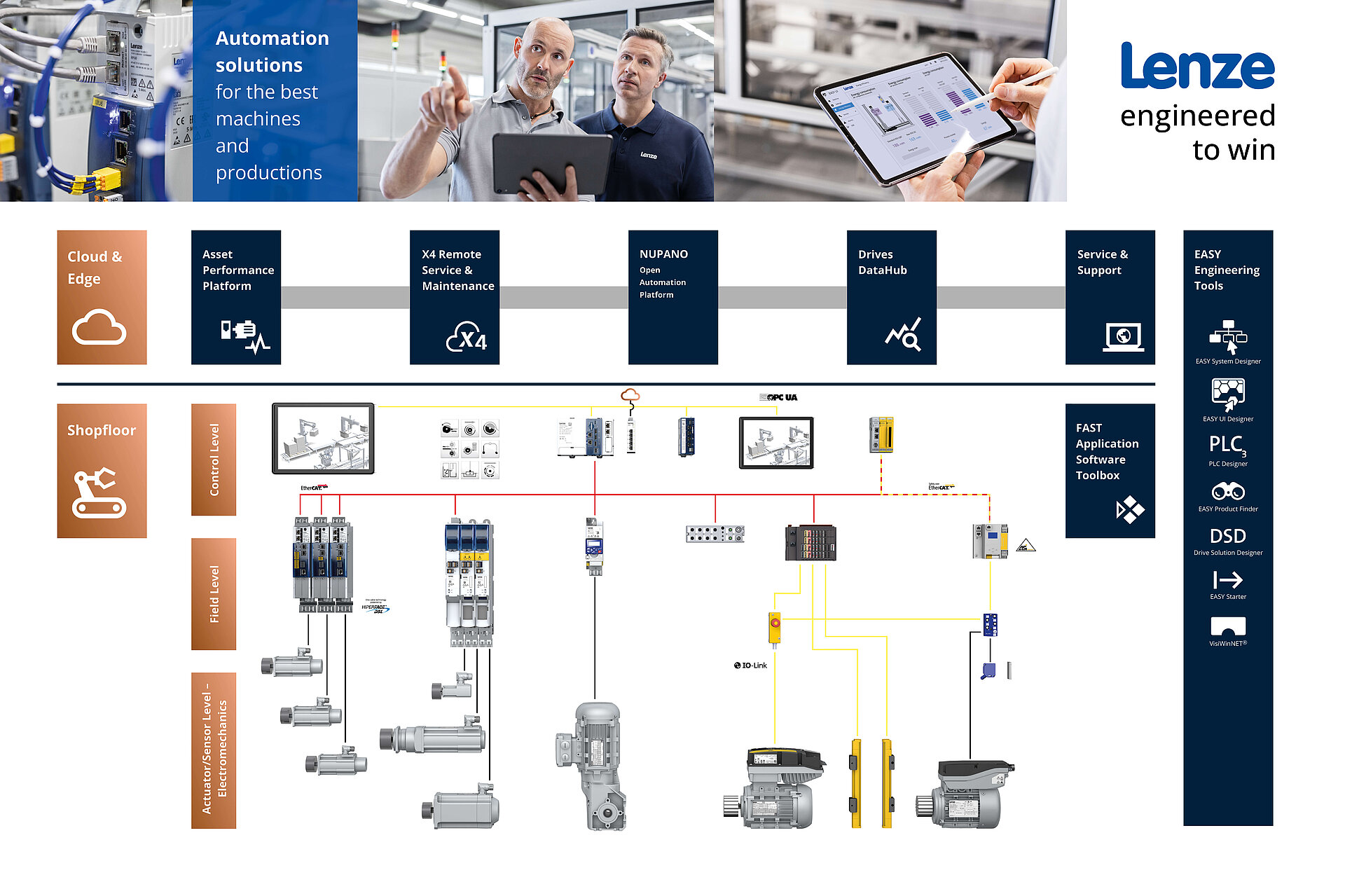

Our comprehensive automation portfolio covers everything from the control level to the field level and the electromechanics. Enjoy maximum flexibility for a completely new range of possibilities in your application.

Energy efficiency

Our drives are designed for low energy consumption. They have intelligent functions such as an energy-saving mode, automatic adjustment of the output frequency to the load and recovery of braking energy into the grid. The drives comply with the EN IEC 61800-9-2 standard, which came into force in 2020.

Scalability & modularity

With their modular design Lenze drives fit into any drive and machine concept with easy handling. You can choose from various communication, safety and I/O modules to create the right interface for your machine or system. You can also use optional extensions such as a keypad or a WLAN module to simplify commissioning and diagnostics.

The Lenze i500 und i650 frequency drive platform delivers powerful, energy-saving motion across all performance levels – from ultra-compact cabinet designs to robust solutions up to 132 kW. For harsh environments, the i500 protec series takes this performance outside the cabinet with decentralized, scalable drives up to 75 kW. And with the motec series and new i650, decentralized integration reaches the next generation: the world’s smallest decentralized control cabinet, featuring advanced functionality, multi-Ethernet connectivity, and regenerative energy feedback.

i650 motec

The i650 motec is the next generation of decentralized frequency drives. With integrated Logic PLC, position control, and safety via CIP Safety, it replaces classic control cabinets—compact, pluggable, and powerful. Standard energy recovery, IO-Link master, and multi-Ethernet interface make it the ideal solution for modular and energy-efficient machines.

i750, i950, and i950 Multi Drive – covers everything from precise single-axis motion to complex multi-axis systems. The i750 is designed for centralized architectures and features One-Cable-Technology for reduced wiring, faster installation, and a compact cabinet design. The i950 offers flexibility for centralized, decentralized, and hybrid setups, with a power range up to 110 kW for both compact and demanding applications. For scalable multi-axis systems, the i950 Multi Drive uses a DC bus system to enable lean machine architecture with minimal wiring and high overload capability. All drives deliver high control performance, dynamic motion, and integrated safety functions such as STO for reliable operation.

i950 cabinet

Efficient motion control in demanding servo applications. The intelligent i950 cabinet can be easily integrated into modular machine solutions with prepared technology applications – parameterization instead of programming. OCT and auto-tuning for controller adjustments add further speed to installation and commissioning.

EASY Engineering tools

We know, that the planning, building and commissioning of a machine is a complex task. This is why we offer you our EASY Engineering tools.

Planning

In the planning phase you need to select the right products, sizes, quotation requests and more. It can be complicated to have an overview over all the necessary data. Our tools help you through the selection process, the planning of your machine and you can even save time and improve the quality of your result.

Implementation

Once you implement your machine our tools help you with the parameterization, configuration, programming, debugging and even with the interface design of your machines.

Operation

As soon as your machine is set up, you will get into the operation process, and the maintenance phase begins. With our tools we make the operation process of machines as easy as possible.