Function:

- When the safety function is requested, the motor is stopped by the laser scanner according to stop category 1 of EN 60204-1.

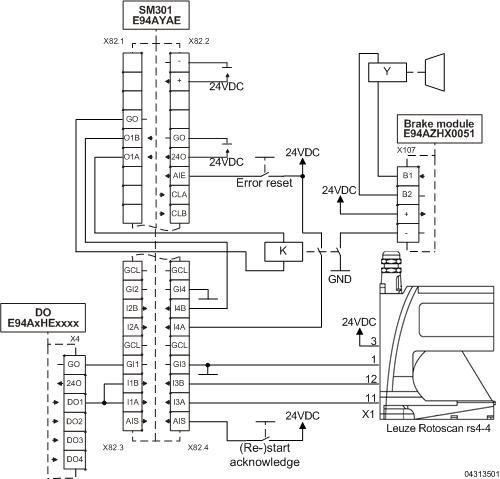

Deceleration to standstill is monitored by the ramp monitoring function of the SM301. This is regarded as the first channel.

If electrical braking through quick stop fails, the mechanical brake is applied and decelerates the motor to standstill. This is regarded as the second channel.

BGIA Report 2/2008 describes this concept in chapter 8.2.23 by means of a connection example.

For safe, single-channel brake control with the SM301, you need a coupling relay. Use a positively driven relay (e.g. Wago 788-384). To check if the relay works correctly, the feedback contact must be connected to a safe input of the SM301. Then, control and feedback are monitored by the discrepancy monitoring of the safe input I4.

Under normal operating conditions, the brake is operated via the 9400 application and the brake module.

To test the brake, the applied torque of the engaged brake is measured. The brake test is carried out via DIGIN 2 every time the LS_SpeedFollower is enabled.

In every brake test, the function of the coupling relay is checked by switching off the safe output of the SM301 via DO1.

Safety information / disclaimer:

The safety application and parameterisation notes are examples of possible subfunctions in machines.The T10D value according to DIN EN ISO 13849-1, Annex C.4.2 is only indicated if a B10D value is available and the operating time is less than 20 years. Commissioning is prohibited until the machine has been checked in accordance with the regulations set out in the relevant EU directives / national laws. The safety instructions contained in the technical documentation must be observed. Using the examples does not exempt the user from careful project planning. For possible damages and consequential damages Lenze assumes no liability to the extent permitted by law. Copyright 2019 Lenze Automation GmbH