Productivity boost for warehouse logistics

The INTELIS PTS shuttle system from Savoye, which was specially developed for "goods-to-man" applications, is currently one of the fastest solutions for automated storage for totes, compartments and cartons in high-bay warehouses. The drive technology required for this has been developed in close cooperation with Lenze. INTELIS PTS is built to make picking more convenient and productive, especially in e-commerce, by providing a faster product-to-human connection.

Fastest system on the market

"The shape of the acceleration and deceleration ramps was among the trickiest points during development," explains Nicolas Guillot, product and marketing manager at Savoye. Acceleration and also deceleration in front of a target must be done so sensitively that the load on the shuttle is always transported in a process-safe manner. On the other hand, too slow a speed has an impact on productivity - which requires a difficult balancing act. Savoye, together with Lenze, has succeeded in this balancing act to such an extent that the French manufacturer refers to the INTELIS PTS as the fastest system on the market. On a rack aisle with 22 storage levels, up to 1100 storage cycles per hour are achieved. The current competitive benchmark is between 500 and 700, according to the product and marketing manager.

Complete solution: drive and automation from a single source

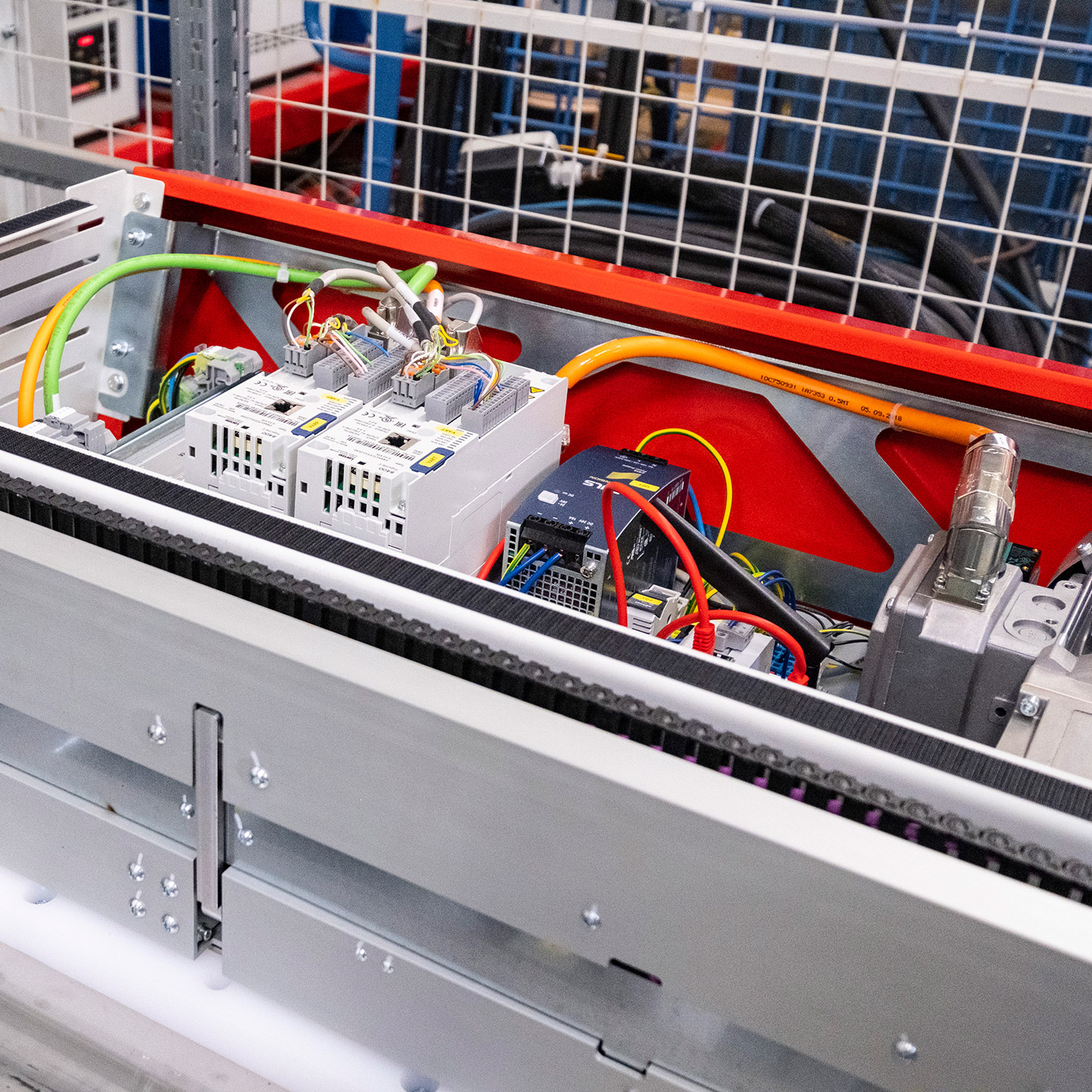

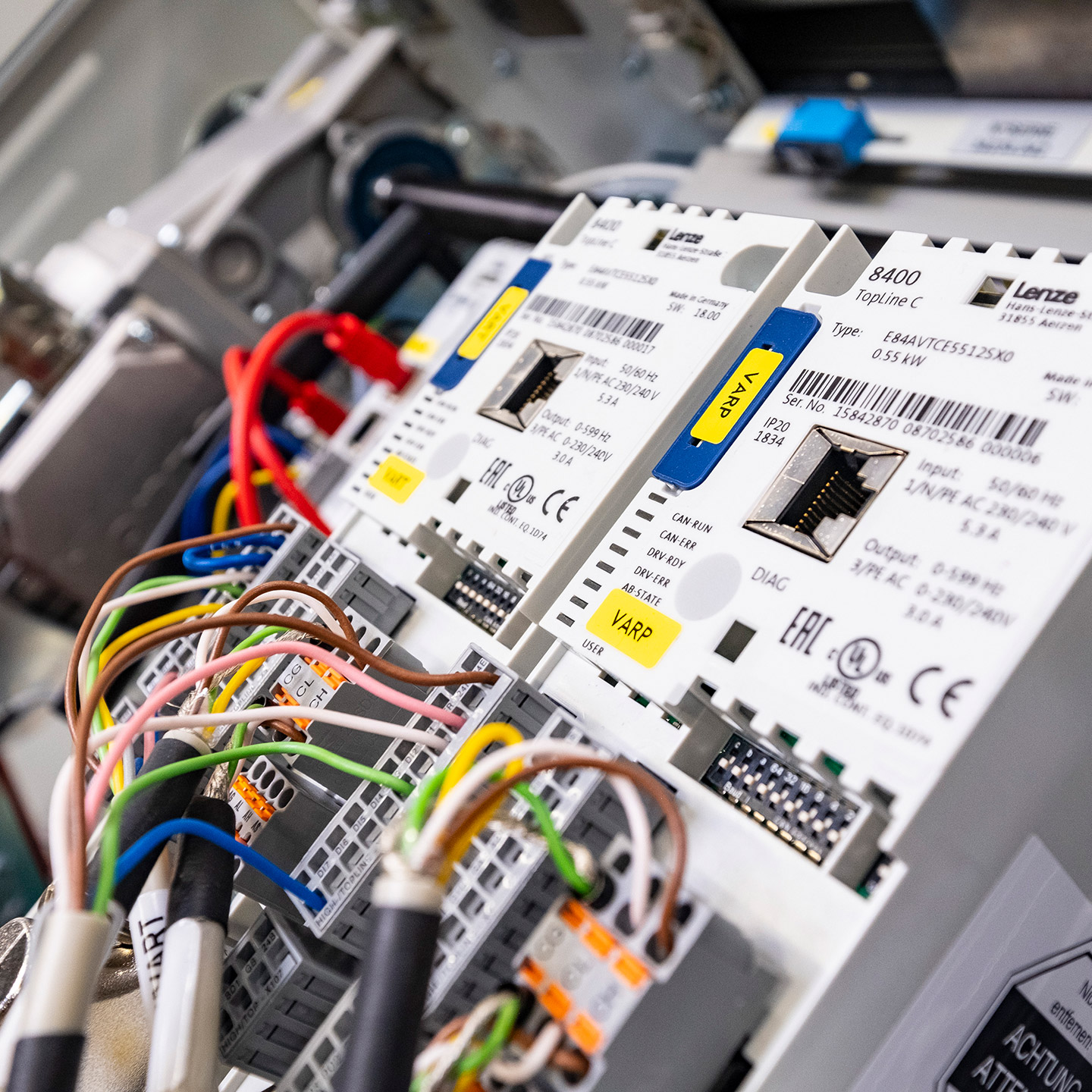

The head element of the drive and automation solution, which was designed and adapted by Lenze to suit the specific application, is the Lenze c300 controller. This communicates wirelessly with the higher-level logistics computer and receives its picking orders in the form of target specifications or warehouse position information. The Lenze controller independently calculates the movement details to be derived from this according to the position of the shuttle.

The interaction between precise positioning on the one hand and fast travel profiles on the other makes it clear that the underlying drive technology in engineering is a demanding task. According to the product and marketing manager, Savoye chose automation solutions from Lenze "because Lenze was the only company capable of meeting Savoye's complete needs." This was preceded by close collaboration during the early engineering phase - ultimately with the aim of evaluating device combinations that best fit the application. Lenze therefore also accompanied the prototype phase with test devices. Application engineers from France and Germany worked together on configuring and optimizing the settings, such as defining the acceleration and deceleration ramps mentioned above.