Energy-

efficient

drive solutions

Energy-efficient drive solutions for industry and the environment

Pro Climate - Why are we talking about energy efficiency in industry?

Sustainability and climate protection already play an increasingly important role in the private sphere. In industry, too, the importance is increasing: In order to reconcile climate targets with a growing and prosperity-oriented society, increasing energy efficiency in industry is a key lever for reducing energy requirements and limiting global warming. Drive systems are responsible for about 70% of the electricity demand in industry. This makes them the biggest lever for increasing energy efficiency and reducing energy demand. The mechanical engineering industry is facing increasing legal requirements, such as the Ecodesign Directive, and the growing desire of users. Lenze provides concrete and holistic support in optimizing the energy requirements of machines with energy-efficient drive solutions.

Learn all about the biggest potential savings in your machine in our new flyer.

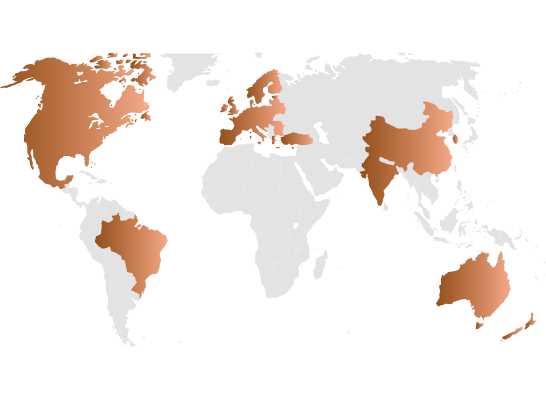

International requirements for energy efficiency

The IEC60034-30-1 standard describes energy efficiency classes for three-phase motors using IE codes. However, the standard does not specify any efficiency classes to be complied with. This is done in the regional legislation. As a result, there are requirements for the minimum efficiency of electric motors in almost all markets. We have prepared these country-specific requirements clearly for you and they are available for download here.

Fact-Sheet Downloads

Fact Sheet Overview

Fact Sheet Australia & New Zealand

Fact Sheet Brazil

Fact Sheet Canada

Fact Sheet China

Fact Sheet Europe

Fact Sheet India

Fact Sheet South Korea

Fact Sheet Mexico

Fact Sheet Switzerland

Fact Sheet Turkey

Fact Sheet UK

Fact Sheet USA

CEMEP guide on ecodesign requirements

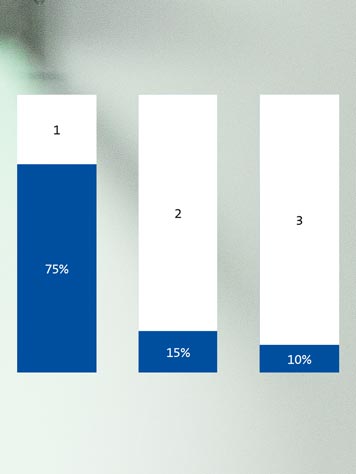

Three approaches are pursued in order to increase the energy efficiency of drives

1. Using electrical energy intelligently: as little as possible

- Dimensioning according to needs

- Controlled operation (frequency inverter)

- Energy-efficient motion control

2. Converting energy with a high degree of efficiency

- Components with a high degree of efficiency:

motors, gearboxes, inverters

3. Using recovered braking energy

- Energy exchange between several drives

- Temporary storage of braking energy

- Regeneration of braking energy

What energy-efficient drive solutions does Lenze offer?

Lenze m550 three-phase AC motors already meet all current and known planned energy efficiency regulations, such as efficiency classes IE2 and IE3. In combination with the efficient g500 gearboxes and i550 inverters, this represents a complete and energy-efficient drive package to realize initial savings potential:

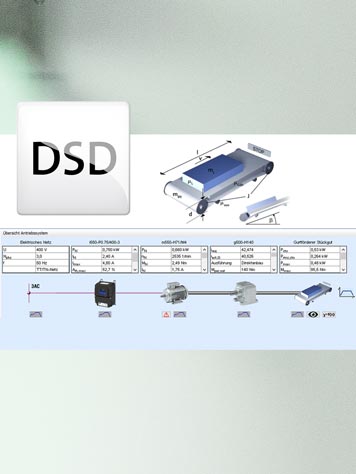

Intelligent drive sizing is a prerequisite for an exactly dimensioned and therefore small-as-possible drive solution with just the right components. Thanks to Drive Solution Designer DSD potential energy savings can be seen at a glance and are documented in the Energy Performance Certificate. A clear comparison of different solutions is also made easy.

After all, the Drive Solution Designer DSD provides a simple view of complex sizing knowledge, with well-founded expertise of drive applications such as drive physics, variants or energy efficiency. Drives are sized based on calculations with individual process data and speed profiles, taking the complete structure of the drive into consideration for the requirements of the machine.

Find out why saving energy is ecologically valuable and economically makes sense.

Optimize the energy efficiency of machines beyond the legal minimum requirements of the Ecodesign Directive. See how tool-supported drive design with Drive Solution Designer DSD further optimizes motion control and further reduces energy requirements.