Intralogistics solutions in warehouses, airports, and distribution centers will significantly benefit from the endless opportunities of our new magnetic drive motor-driven roller.

The active gearless MDR is suitable for a wide range of applications in your conveyor systems.

- Up to 2X as powerful as other MDRs thanks to innovative motor design

- 30% energy savings compared to a conventional MDR and efficiency level upward IE7 – IE9

- Quiet operation with a design based on the Vernier principle

- Minimal variance: One covering all speed and torques

- Voltage flexibility: A single variant can run on 24 and 48 VDC

Data: Motor driven roller o450

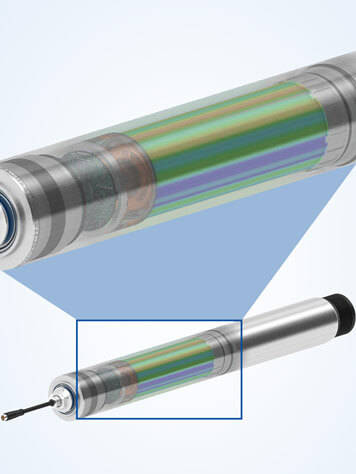

The new o450 MDR enables precision speed control during transport while delivering twice the power of conventional motorized rollers thanks to its unique brushless motor design. This innovative design utilizes a magnetic gear effect, making the o450 MDR powerful and efficient. The power electronics are integrated inside the roller, offering a compact solution for your most challenging applications.

The o450 MDR is gearless and will reduce variants by up to 85%. By simplifying the multiple touchpoints in your operation, you can minimize inventory with fewer design variables. This unique MDR will maximize flexibility from both an operational and maintenance perspective. With fewer stocked items, you are much more flexible and can solve the many different applications in loads and speeds that are common in intralogistics. Therefore, you can cover a wide range of solutions with far fewer components. Universally deployable are 24 V (57 W) or 48 V (110 W). And did we mention that the new MDR can be easily integrated into many systems?

Cost and energy savings result from the compact and gearless design; friction losses are eliminated. The efficiency of the MDR is 30% higher than conventional motor rollers with gears. As a good corporate citizen, we always look toward the future regarding sustainability. As a result, the o450 motor design uses less active material. Additionally, this MDR is based on a newly developed magnet type that uses 30% less rare earth materials than conventional magnets; in total, that means more than 50% reduction in rare earth materials.

The new o450 MDR in 24 V / 48 V is a true pacesetter for your application and silently accelerates with 5 Nm peak up to 1.5 m/s and with a nominal torque of 1.35 Nm. The innovative permanent magnet motor represents a new drive concept. Use it to successfully design accumulating conveyors, roller conveyors, and other dynamic conveyors.

The NEW o450 MDR is now available. Visit booth B4224 at MODEX or contact us at 800-217-9100 to have a sales leader walk through how this evolution in conveyor technology will transform your intralogistics operation.

Vernier principle:

Creates a magnetic gear effect

Accumulating roller conveyors and roller conveyors

Smooth operation

The horizontal transportation of crates, cartons, or highly sensitive goods in polybags are some of the myriad scenarios where the Lenze o450 MDR is ideally suited to impact your operation. Whether you want to drive belt conveyors or move products more efficiently, we guarantee smooth conveying ahead.

Diverter

Dynamic response

Parcel shipments are in the billions yearly with no signs of slowing down. Therefore, parcel logistics needs efficient, dynamic, and reliable conveyor solutions that evolve with the business. The o450 MDR will drive you forward, providing a flexible solution for challenging environments like sorting.

Cross conveyor

Fast change of direction

When complex conveying needs multi-directional solutions, the o450 MDR rises above the rest. Varying directional movements in industrial applications are common, and the o450 MDR provides possible peak torques of up to 5Nm, offering endless opportunities in your conveying operation.